|

|

Case Study - Package Power Utility Boiler Burner and Induced Flue Gas Recirculation SystemProblem:

Unit Description: Foster‐Wheeler type AGA 5150S monowall fired balanced draft package boiler. The boiler is equipped with a Ljungstrom air heater, forced draft (FD) fan and induced draft (ID fan). Solution: STEP combustion provided our dual fuel (heavy oil and natural gas) burners with class 1 natural gas igniters to replace the baseline configuration. The burners were designed to fit the existing windbox, and customized to provide air slides for combustion air control, oil gun automatic retract and gun coupled limit switches. Additionally, an induced flue gas recirculation (IFGR) system was designed and provided to further reduce gas and oil NOx emissions.

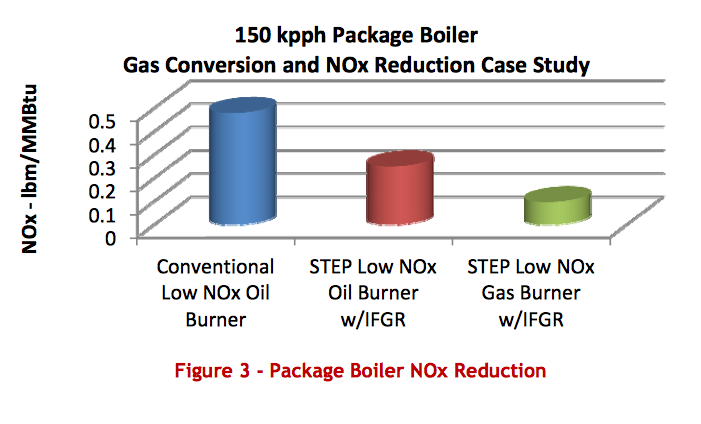

NOx emissions were reduced from a baseline NOx emissions of approximately 0.50 lbm/MMBtu to less than 0.28 lbm/MMBtu while firing oil and less than 0.10 lbm/MMBtu firing gas with the IFGR. NOx reductions were achieved while maintaining CO and opacity at or below baseline levels. Download PDF of this case study To speak to a representative, find a local sales representative,

|

A power utility needed to convert their single fuel (heavy oil) to dual fuel (heavy oil and natural gas) boilers and reduce NOx emissions.

A power utility needed to convert their single fuel (heavy oil) to dual fuel (heavy oil and natural gas) boilers and reduce NOx emissions.  Results:

Results: