|

|

Case Study - Reduce Burner Trips and Opacity Spiking with Transient Piping AnalysisProblem: A utility boiler was experiencing regular opacity spiking during startâ€up, along with burner trips and instability. Recent operation as a peaking unit with a high frequency of starts and stops, the utility needed to improve the opacity and reliability during lightâ€off and warmâ€up. Solution:

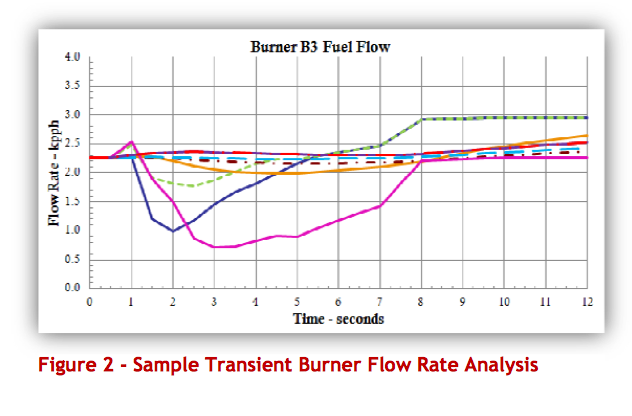

Through transient analysis (with specially developed correlations for atomizer performance), STEP was able to match observed field conditions. Once the validated model was obtained, STEP modeled changes to the sequences such as fuel pressure "kickers", adjusted timing, and more, as well as hardware changes. Numerical analyses were both quick and efficient without the expense and other problems (opacity, manpower, etc) associated with field trials. Results:

Download PDF of this case study To speak to a representative, find a local sales representative,

|

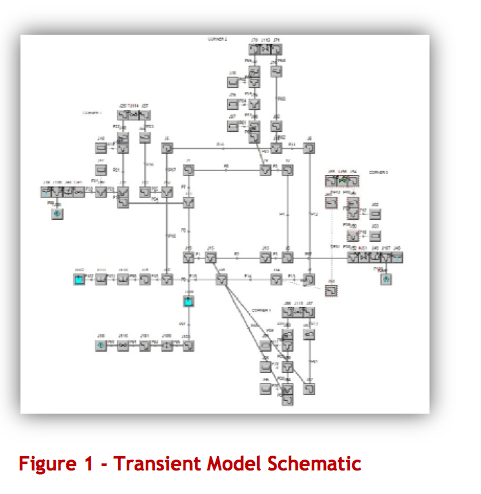

STEP performed an onsite evaluation and was able to determine that the burner trips, instability, and opacity were a result of burner pressure fluctuations during lightâ€off. STEP proposed a transient hydraulic analysis of the burner lightâ€off sequence (for the first three burners placed into service) including: supply piping, return piping, steam purge, atomizing steam, and fuel oil supply characteristics. A computer model of the system was created and is illustrated in Figure 1.

STEP performed an onsite evaluation and was able to determine that the burner trips, instability, and opacity were a result of burner pressure fluctuations during lightâ€off. STEP proposed a transient hydraulic analysis of the burner lightâ€off sequence (for the first three burners placed into service) including: supply piping, return piping, steam purge, atomizing steam, and fuel oil supply characteristics. A computer model of the system was created and is illustrated in Figure 1.