Case Study - Gas Conversion and Low NOx Retrofit of a 450 kpph Tangentially Fired Boiler

Problem:

A North American utility company needed to convert a tilting tangential oil‐fired boiler to a dual fuel (natural gas and oil) unit. Additionally, heavy oil NOx emissions were to be reduced from the current low NOx burner levels.

.

Unit Description: CE tangential #6 oil fired VE superheat unit. Eight (8) tilting tangential burners with two (2) burners per corner and eight (8) class 1 light oil igniters. The unit was designed to supply 450 kpph of steam at 1475 psig and 955 °F.

Solution:

STEP provided 8 dual fuel 90MMBtu/hr Low NOx natural gas and heavy oil burners for each boiler. The burners were equipped with automatic retracts and gun coupled limit switches. STEP also provided Class 1 natural gas igniters with flame detection rods, and UV+IR+V fiber optic main flame scanners, tuned for individual burner discrimination. STEP provided 8 dual fuel 90MMBtu/hr Low NOx natural gas and heavy oil burners for each boiler. The burners were equipped with automatic retracts and gun coupled limit switches. STEP also provided Class 1 natural gas igniters with flame detection rods, and UV+IR+V fiber optic main flame scanners, tuned for individual burner discrimination.

Results:

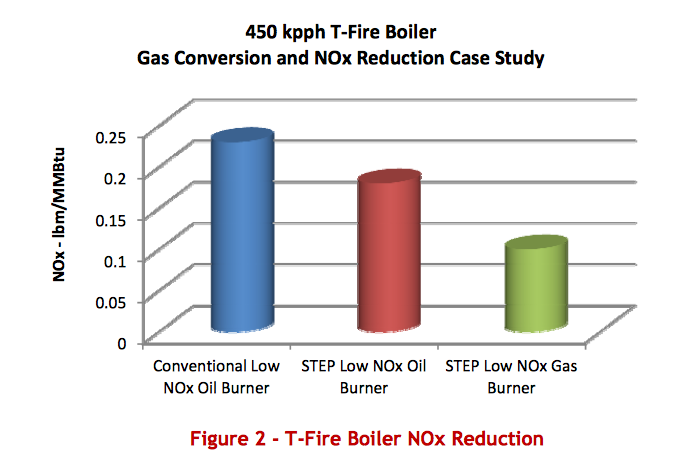

Both gas and oil performance surpassed the guarantees. The new burner reduced heavy oil NOx emissions by 25%, while natural gas NOx emissions of less than 0.1 lbm/MMBtu were achieved. The low NOx performance was achieved without the use of flue gas recirculation or over‐fire‐air, while maintaining low CO and opacity.

.

Download PDF of this case study

To speak to a representative, find a local sales representative,

or a free consultation call us at 203-452-STEP (7837) or click here to email us.

|