|

|

Case Study- Electrostatic Precipitator Capture Efficiency ImprovementsProblem: A utility boiler equipped with a cold‐side electro‐static precipitator (ESP) is subject to chronic elevated opacity levels. Solution: STEP was contracted to evaluate the current electro‐static precipitator (ESP) configuration and conduct field testing. Based on velocity measurements in the ESP ducting, it was determined that mal‐distributions in the flue gas flow, were contributing to the constant elevated opacity levels.

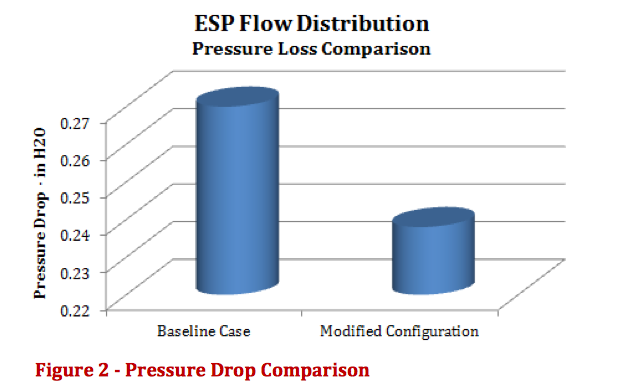

Accordingly, several inlet configurations were designed and modeled to assess the impact to velocities and pressure drop across the ESP. Results: Various design configurations were modeled, and an economical modification to the inlet ductwork was selected. The modification included the addition of flow distribution plates and modification of the existing configuration. The implemented changes resulted in the reduction of peak velocities by over 21%. The implemented changes, which provide better airflow distribution within the ESP and better capture efficiency, reduced unit opacity by more than 5% at low to mid loads and approximately 10% at max load conditions, while reducing pressure drop across the ESP.

. Download PDF of this case study To speak to a representative, find a local sales representative,

|

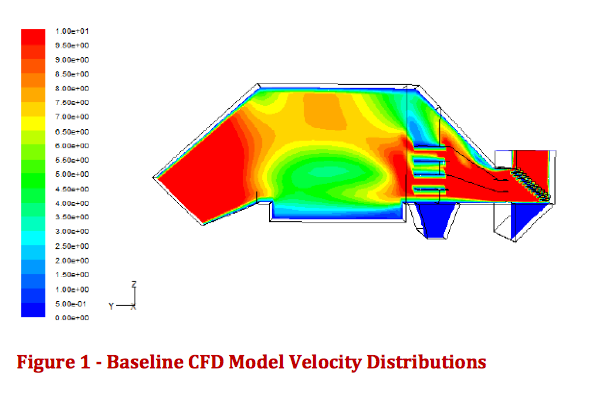

In order to validate the observed test results and changes to the duct and vane configuration, a numerical model of the ESP and inlet ductwork was created. The baseline model was validated against field test results and showed that the existing flow distribution vanes were inadequate in balancing the flow into the ESP.

In order to validate the observed test results and changes to the duct and vane configuration, a numerical model of the ESP and inlet ductwork was created. The baseline model was validated against field test results and showed that the existing flow distribution vanes were inadequate in balancing the flow into the ESP.