|

|

Case Study - Combustion Diagnostic TestingProblem: A utility boiler was de‐rated due to elevated opacity levels during high load operation. STEP was contracted to provide field diagnostics in order to evaluate the root cause of the elevated opacity as well as to provide an action plan for opacity mitigation and future preventative measures. Unit Description: The unit is a Foster Wheeler wall‐fired 800+ MW utility boiler equipped with 30 burners arranged in 5 rows of 6 burner columns. . Solution:

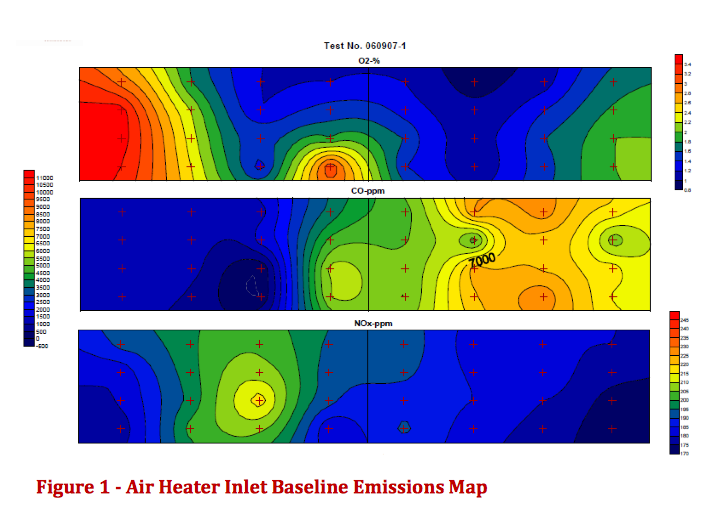

Results: Inspection of each burner highlighted several issues with the existing combustion hardware including missing flame stabilizers, clogged or dirty burner nozzles, and poor firing configurations. Operating and emissions data were obtained and performance was evaluated at different operating conditions. STEP examined the effects of burner firing patterns, burner settings (air and fuel), air and fuel flow distributions, flue gas recirculation, and more. With the extensive testing conducted, STEP was able to map back‐end emissions to specific burner regions. The mapping facilitated diagnostics as well as associated unit/burner tuning. After addressing the burner issues, and implementing the tuned settings, opacity was reduced reinstating operating at the normal full load capacity. Download PDF of this case study To speak to a representative, find a local sales representative,

|

STEP performed a thorough performance evaluation including emissions mapping at the air heater inlet to establish baseline operating conditions and to evaluate the effects of burner and operational changes.

STEP performed a thorough performance evaluation including emissions mapping at the air heater inlet to establish baseline operating conditions and to evaluate the effects of burner and operational changes.